What is TPE(Thermoplastic Elastomers) ?

Thermoplastic Elastomers (TPE) are materials that can be processed in all processing methods that are used for plastic materials, while having high strength as a vulcanized rubber without needing vulcanization process. These are the general characteristics;

General Properties:

- Have low density

- It can be produced in a wide hardness range,

- Are highly resistant to UV & Ozone,

- Functions in a wide temperature range,

- Are 100% recyclable

- Have low permanent deformation value,

- And can be colored for the desired needs

- Need low production and investment cost

As a result of all these features, they are preferred, especially in the plastics gasket industry.

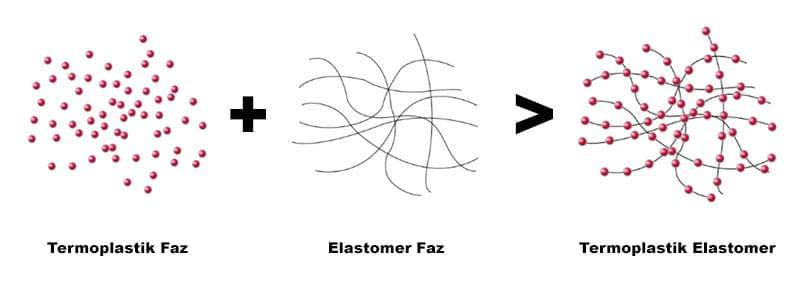

TPEs generally consist of a soft and a more rigid hardness phase.

Thanks to this structural feature, they have both flexibility, elasticity, and weather resistance properties of rubber materials while having temperature resistance, strength, and processability properties of thermoplastic materials.

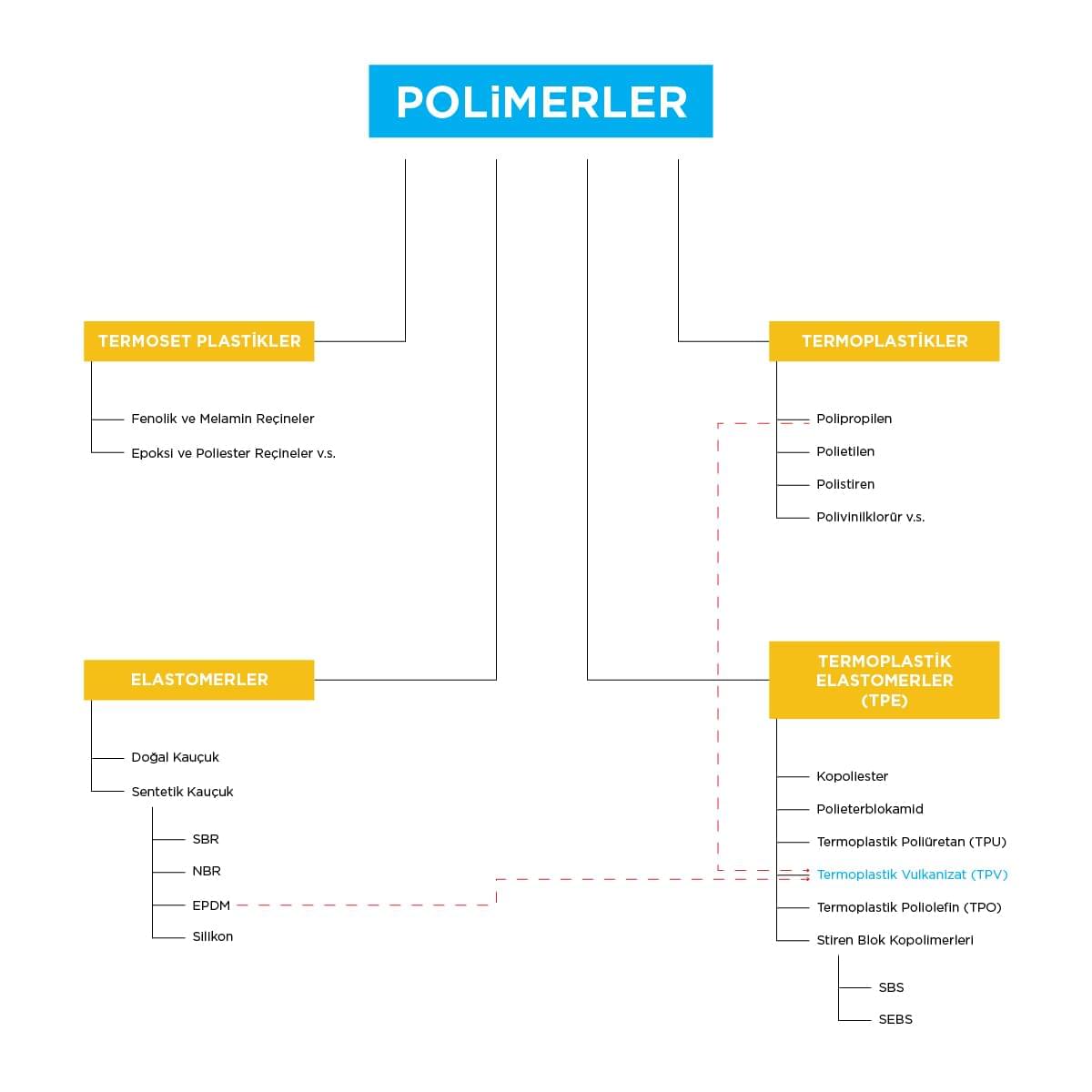

As you can see from the Polymer Tree, TPE, Thermoplastic Elastomers, is one of the four main groups of polymers.

Thermoplastic Elastomers (TPE) have the following sub-types according to their structures:

- Thermoplastic Vulcanizates (TPV)

- Styrenic Block Copolymers (SBS, SEBS)

- Thermoplastic Polyolefin (TPO)

- Thermoplastic Polyurethane (TPU)

- Polyether-block-amide

- Copolyester

What is TPV?

TPV (EPDM/PP) Thermoplastic Vulcanizates are obtained by mixing the thermoplastic phase (PP) and rubber phase (EPDM) to create a homogeneous and balanced phase distribution and then adding vulcanization chemicals into this homogeneous phase mixture. TPVs (EPDM/PP) obtained by this method has the characteristic properties of EPDM, such as elasticity, UV & Ozone resistance, and low permanent deformation. At the same time, they can also be processed through extrusion and injection methods.

What are the Properties of Thermoplastic Elastomers (TPE)?

Hardness

Thermoplastic Elastomers (TPE) can be obtained in a wide range of desired hardness, from 20 Shore A to 70 Shore D.

UV&Ozone resistance

Thermoplastic Elastomers (TPE) are materials with excellent UV & Ozone resistance.

Resistance to Hot/Cold

Thermoplastic Elastomers (TPE) have an instantaneous working temperature between -40 and +130 C. Therefore, they can be used in a broad regional area, for example, From Northern countries such as Canada to South American countries like Mexico.

Color Options

Many colors can be obtained with Thermoplastic Elastomers (TPE). They can be produced in all colors in the RAL catalog.

Recyclability

Since Thermoplastic Elastomers (TPE) can be reused, they are environmentally friendly materials that do not harm the environment and nature.

Weldability

Thermoplastic Elastomers (TPE) can be bonded with heat. They can be used in co-extrusion and co-injection methods to create products with different hardnesses. And that also gives an advantage for projects that requires welding. (like corner welding, which is crucial for the refrigerator gaskets and trailer gaskets.)

Permanent Deformation

Thermoplastic Elastomers (TPE) offer low permanent deformation values in both dynamic and static applications, thanks to the elastomer phase in their structure.

What are the Usage Areas of Thermoplastic Elastomers (TPE)?

TPE Usage Areas:

TPEs (Thermoplastic Elastomers) are preferred over traditional thermoset elastomers due to their recyclability, especially as environmental awareness gains more importance. By offering advantages such as ease of the process, ability to be co-extruded, applied in the same mold with suitable Thermoplastics (PP, ABS, PE, etc.), being able to be colored, and having a wide hardness range, TPEs are highly preferred in medical, automotive, construction, electrical, device, packaging, and industrial applications.